Phil and Teresa DeWalt were here on his way back from Kalamazoo and the annual CMSA conference, September 25, (2022) and he left the next morning. He left an RCA 45 rpm record player, the 45-EY2. The idea was that, when I got a chance, I should take a look at it and see what I could do. He reported that the platter didn’t turn, and it hummed like a sonofabitch. These things are sought after by collectors. In good condition, properly restored, they can fetch a good price. There’s plenty of info about them on youtube and the web. Phil got this one at a junk shop for $29, with his senior discount.

I didn’t really bother to take an external ‘before’ photo. Nor did I repeat Phil’s ‘plug it in and see what happens’ test. I took his word for it, and I jumped right in to taking it apart.

Taking the bottom cover off – easy. Taking the amp out – fairly easy.

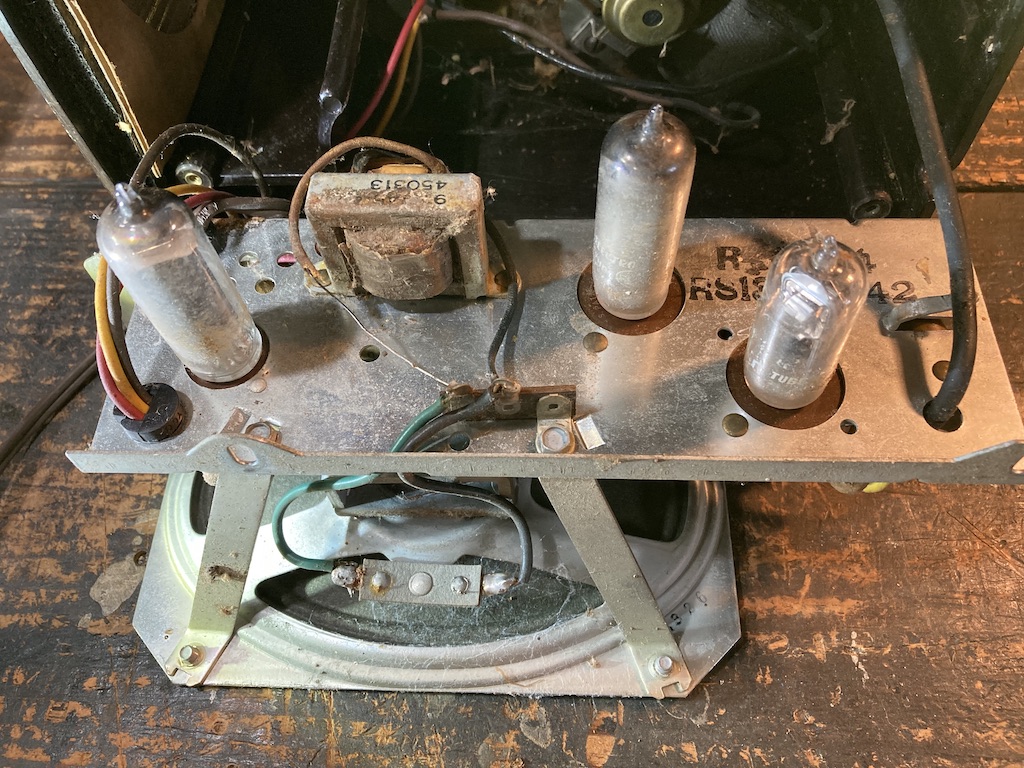

Disassembly of the amp began with unscrewing the speaker. The speaker looked very good. No tears, good feel, no grating of the voice coil when gently moved in the magnet. Every one of those electrolytic caps has to be replaced.

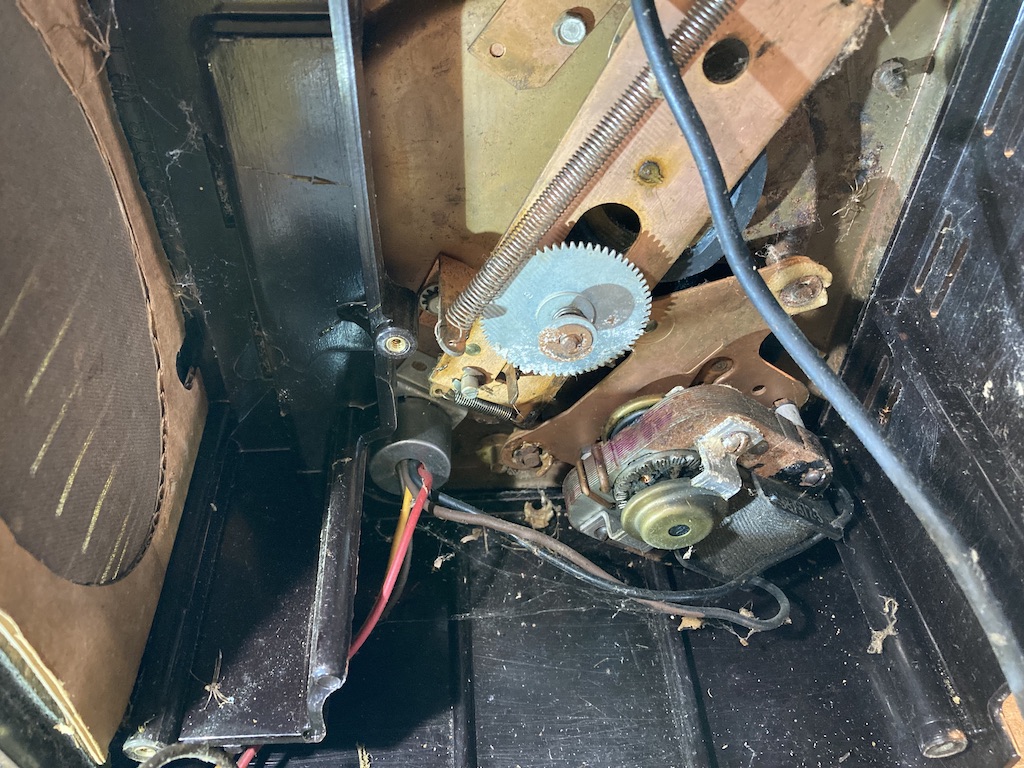

Getting the changer mechanism out was more challenging. It only goes out one way, unless you want to unsolder a bunch of stuff, and I did not.

The insects are par for the course; the water damage is more alarming. I pressed on. I ordered parts. Mechanical parts came from the “Redhead,” Sally Jeffries at eBay. Of course, there’s no way to know if Sally is a real human female, or just the name of the business. And as for ‘redhead,’ that seems to be the name of their replacement cartridge. The cartridge as found was not the original, was some poorly installed Varco replacement, and was likely to be belly up.

Electronic parts are also available on eBay in kits. I put in my orders. I hit the pause button, consulting all the while with Phil by text message.

The amp parts arrived first. I have lots of practice re-capping amps, and I’ve build from scratch one of these 3 tube filament-in-series amps. This one is the later 35w4, 50c5, 12av6 versions. This is the classic circuit that uses the filaments in series to drop the line voltage. The so-called “all American five” radio sets used these tubes for amplification, but they have an easier time of it, since five filaments will drop more of the 120 VAC coming in. In the day, the house current voltage was a bit lower, more like 110 VAC. So there has to be a big wire-wound resistor at the top of the filament string to handle that. There is; it’s R9 in the RCA EY2 schematic, and it needs to be about 120 ohms and be able to handle 5 watts. Installing the capacitors was fairly easy. The only difficulty was in getting at them. The one on the volume pot put up the most fight, but, as usual, I won. Testing the amp, I had some hum, but not the severe hum Phil reported. The Varco cartridge proved to be indeed dead. So the only check I could do was to inject some 60 cycle hum by touching the input lead. On, then, to the mechanical stuff.

The parts from the ‘redhead’ were packaged out the wazoo, and the instructions were a hoot. Here’s an example:

I ran out of acetone pretty quickly and was too lazy to go back to the hardware store for it. So I used mineral spirits to de-grease. Also, I was not going to wait for the solvent to dissolve the rubber. It peeled off easily enough on its own. Good riddance to bad rubber.

The sliding platform and its bracket pictured here got a soak in the spirit bath:

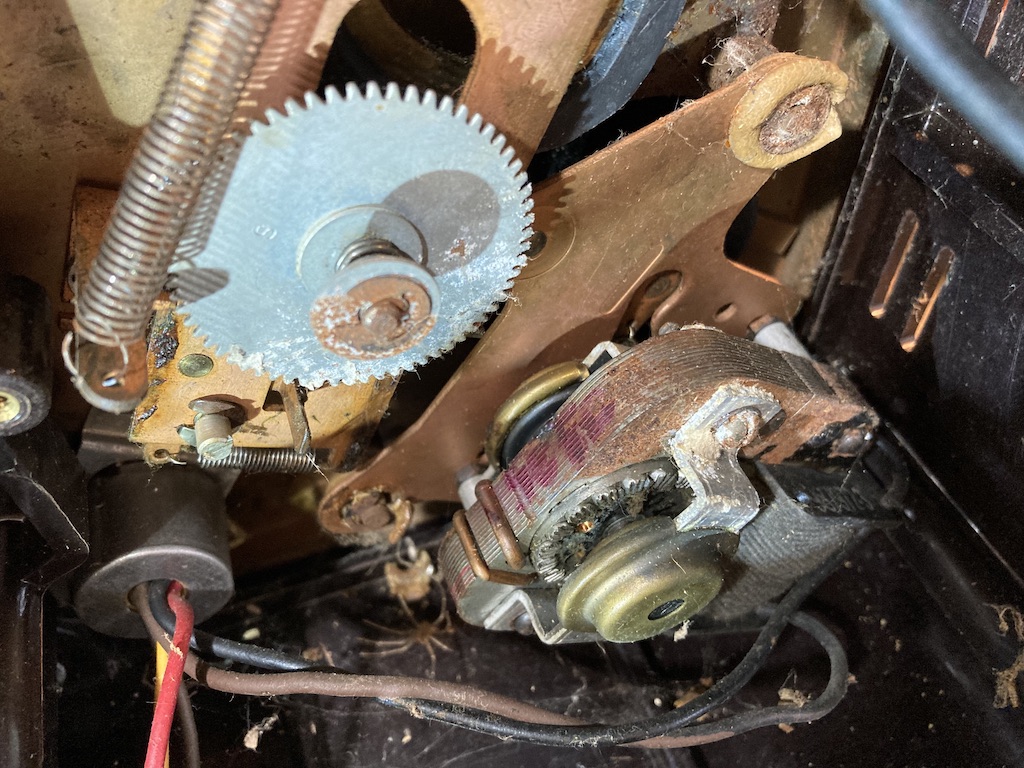

For lubricant, in the sliding parts, I used a synthetic stay-put knock off. It looks like Vaseline, but it isn’t. In the photo, you can see the motor off to the side with new motor mounts. It got a good lubrication also, with the included SAE 10 weight. Lots of details here: note the wire nut over the bare wires connecting the hot lead to the cartridge. Seemed like prudence to me. The big knob that retains the sliding bar (the heart of the mechanism) adjusts the tone arm height. The spindle is out in this shot. As it turned out, there’s not much left over energy from the motor to overcome the extra friction of old grease and dead spiders. So I had to take the spindle apart, clean it, and re-lube it.

After reassembly, it was time once again for testing. Tested all along, but thrice with a full stack of records. For the first test of a stack, I played a stack of 10 in the living room. It got stuck after awhile and wouldn’t reliably cycle. Back to the bench, I did cleaned up the spindle, as noted above. Another trip to the living room, more successful. Then, after a cool down period, I took the unit upstairs to the bedroom, where I played another stack of 10. Del, my wife, enjoyed both stacks. As Gib Epling used to say on his West Tech website, as the records spin, let the memories begin. Having now gotten this unit boxed up for Phil, I’m considering getting the changer only version myself. I have plenty of amps here that will play a ceramic cartridge output. But I’ve sort of fallen in love with RCA’s rotating spindle mechanism. Didn’t they, after all, invent the 45 rpm record?